Palisade Fences, Galvanized, Powder Coated, Black Finishes

- Hot Dipped Galvanised Palisade Fencing

- Powder Coated Galv. Steel Palisade Fence

- Wrought Iron Palisade Fence

Steel Palisade Pale Types

Fencing Heads Shapes

- Palisade Fencing Tops General Intro

- Palisade Fence with Round and Notched Top

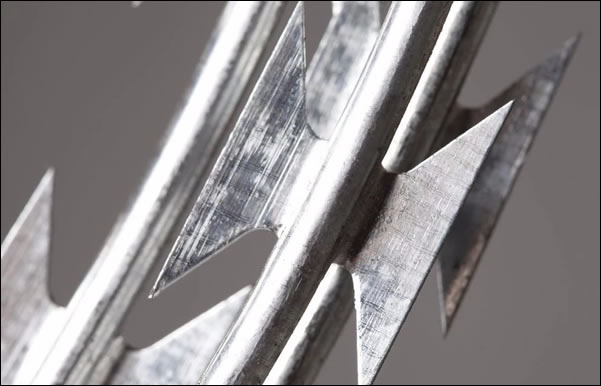

- Triple Spike Pointed Palisade Fence

- Single Pointed Palisade Fence

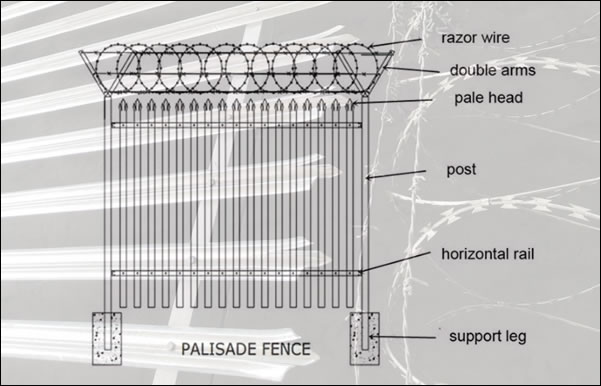

High Security Fence Systems

MODULAR PALISADE SECURITY FENCING SYSTEM

Typical high security palisade fencing system has the following:

Steel palisade panels;

Steel palisade gates;

Top rail security spikes; and / or

Razor flat wrap; and / or

Razor coil.

All material shall be hot dip galvanised to SABS/ISO 1461.

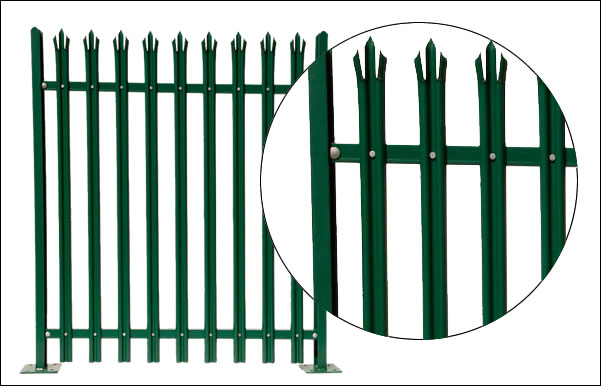

Steel Palisade Panels

The palisade panels are constructed with triple pointed or spear top posts, top rails, razor spikes, bottom rails and accessories.

Modular palisade fence panel with frame post, bottom rail and top rail bolt fixing

Modular palisade panel fixed with horizontal rails bolted at medium position of the panel height

Tubular Fencing Posts

Corner posts must be installed at a 45 deg angle. Two 40 x 40mm taps with a 14mm hole must be welded, at 45 deg, 860mm from the bottom and 2700mm from the bottom on the inside flange of the corner post.

Four M

12 x 40 mm bolts with hex nuts and washers must be used to secure the panels to the post. A 40 x 40 mm tap with a 14mm hole must be welded 525mm from the bottom, on the inside flange of the corner post, for the earth tail connection. There will be occasions when the Posts will be surface mounted and in these instances the Post shall be only 2400mm

long having a 200mm x 200mm x 6mm Base Plate fully welded to the Post. The Base plate shall have Four 14mm Diameter holes positioned at 140mm centres at each corner of the

Base Plate. The Post shall be secured by means of Four 12mm Stainless Steel Chemical Anchors.

Palisade Panels.(Refer to figure 6)

Three normal panel sizes options: 825 x 2350 mm, 1200 x 2350 mm and 2100 x 2350 panels.

Fittings for fixing the panels:

hot dip galvanised cap square bolts, hex nuts and washers, stainless cap square bolts and hex nuts and washers.

Top Rails. (Refer to figure 6)

Material: 50mm x 50mm x 5mm angle iron.

At the end of the rail a 13mm hole must be drilled through the centre for M12 mounting bolts.

Razor spikes must be fitted to top rails by means of 6 mm pre-drilled holes (before galvanising) and secured

with 4.8 mm full stainless steel pop rivets.

Top Rail Security Spikes. Industrial standard high security spikes shall be used.

Bottom Rails. (Refer to figure 6)

Material:

50mm x 50mm x 5mm angle iron.

At the end of the rail a

13.5mm hole must be drilled through the centre for M12 mounting bolts.

Pales.

Pre-formed 2.5mm thick x 65mm wide pales

The pales with a drilled hole, stud welded bolt, or a welded tab for connection to the

horizontal rails. The pale shall be 2350 mm long, and the top must be in the shape of a

spear or trident configuration. The top of the pales must be in line with the top of the posts.

The fence post connections to the horizontal rail will be erected using M12 hot dip galvanised cup square bolts and nuts and washer (inland), and M12 stainless steel bolts, nuts and washer in coastal regions. The threads are to be damaged after installation. The washer is to be inserted on the nut side of the connection, and the nut side shall face toward the inside of the site. No welding is to take place after galvanising. All mild steel bolts shall be treated with mono seal on the nut end after being tightened.

Right gate posts, refer to figure 7; left gate post, refer to figure 8; intermediate post, refer to figure 9; corner post, refer to figure 10.

a. Two 14mm holes, through the web portion, 15mm and 300mm from the bottom of the beam. Two 12mm x 150mm pieces of re-bar must be fitted into the holes, prior to casting of the concrete.

b. Two 14mm holes, through the web portion, 80mm and 160mm from the top of the beam, to mount the razor coil / flat wrap brackets.

c. Four 14mm holes, through the inside flange portions, 860mm and 2700mm from the bottom of the beam, to mount the top and bottom rails.

d. The bottom 650 mm must be painted with black bitumen paint prior to erection.

Steel Palisade Entrance Gates

Pedestrian Gate

Gate frame and pales of 2350 mm height, fabricated from 38 mm x 38 mm x 3 mm square tubing.

The gate shall consist of the following: frame, post, handle, bolt, lock.(Refer to figure 2, figure 4, figure 5)

A 16 mm diameter stainless steel sliding bolt shall be fitted to the gate, with a 5 mm stainless steel tab on the sliding bolt and a 5 mm tab on the gate frame with 20 mm slotted holes, to accommodate a 12 mm padlock. Stainless steel must be grade 304.

A 5 mm thick steel guard plate shall be welded to the gate frame at the position of the sliding bolt to prevent the gate from opening to the inside. The Steel Guard Plate must hide the Sliding Bolt from the front and double as a Handle.

Use pales to match fence. The pales must be bolted to the gate frame with M8 x 80 mm Cup Square bolts and hex nuts with a washer on the nut side. The gate pales shall extend to the same height as the fence pales.

The gate opening shall be 1200 mm wide, allowing for a 30 mm gap between the gate and

posts on the lock side, and a 46 mm gap on the hinge side.

The distance between the concrete apron and the bottom of the gate must be 50 mm.

A rectangular tube horizontal top rail to be fitted with galvanised cup square bolts between the two gate posts. Razor spikes must be fitted to top rails by means of 6 mm pre-drilled holes (before galvanising) and secured with 4.8 mm full stainless steel pop rivets.

Drop Side Hinges manufactured from 6mm thick mild steel material must be used. A protection plate is to be welded across the inner half of the Hinge to prevent tampering with the Hinge Bolt.

All steel used in the construction of the gate shall be hot dip galvanised SABS/ISO 1461.

Frame is made from hot dip galvanised mild steel

square tube or angle iron.

The gate frame is clamped to the

gate and fence for the attachment of the general safety Sign

Motor Gates

Gate frames

shall be fabricated from 38 mm x 38 mm x 3mm square tubing.

Flat bar braces must be welded into the inside corners of the frame to support it (as

per figure 1).

The right hand side of the left gate and the left hand side of the

right gate (the two vertical square tubing's must extend past the bottom horizontal member of

the frame) must be in line with the bottom of the pales.

A stainless steel sliding bolt shall be fitted through the frame on the left hand side of the right hand leaf, with a stainless steel tab on the sliding bolt and a tab on the gate must be offset from the centre line on the gate to accommodate the sliding tab with slotted holes to accommodate a padlock. A second stainless steel sliding bolt will be set in a vertical position on the right hand side of the left gate leaf. This bolt must be set into the vertical slider bottom support (Refer figure 11) and the top of the bolt must have a stainless steel tab with a hole to accommodate a padlock in the same position as the horizontal sliding bolt tab when in the locked position. The sliding mechanism must have three welded 5mm tabs with 20mm holes for the bolt on the inside of the gate frame. The sliding bolt must have an 8mm tab supporting the bolt in the open position welded to the gate frame. A second stainless steel drop bolt will be set in a vertical position on the left hand side of the right gate leaf. (Refer to figure 3) This bolt must be set into another vertical slider bottom support (Refer to figure 11) and the top of the bolt must have a stainless steel 5mm tab. The sliding bolt must have a tab supporting the bolt in the open position welded to the gate frame. Stainless steel must be grade 304.

A steel guard plate shall be welded to the gate frame at the position of the sliding bolt to prevent the gate from opening to the inside. The Steel Guard Plate must hide the Sliding Bolt from the front and double as a Handle.( Refer figure 4 & 5 )

A rectangular tube horizontal top rail shall be bolted to the top of the vertical rails by means of four galvanised cup square bolts. Razor spikes must be fitted to top rails by means of pre-drilled holes (before galvanising) and secured with stainless steel pop rivets.

Drop Side Hinges manufactured from mild steel material must be used. The Hinge Pin is to be replaced with hot dipped galvanized, shaft shank bolt that shall have the thread damaged after installation. A protection plate is to be welded across the inner half of the Hinge to prevent tampering with the Hinge Bolt. The gate shall open outwards.

All steel used in the construction of the gate shall be hot dip galvanised SABS/ISO 1461.

Frame made from hot dip galvanised mild steel

square tube or angle iron.

The frame is clamped to the

gate for the attachment of the safety sign.

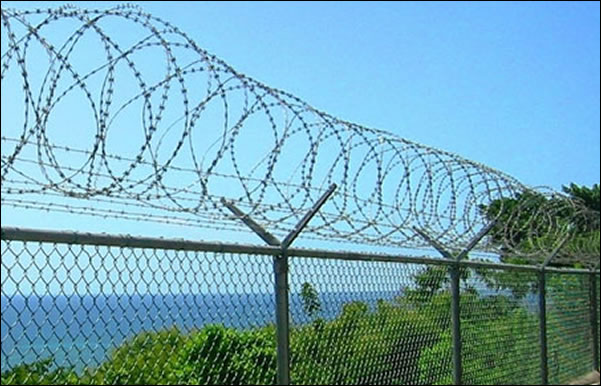

Security Fencing Tops

Options: Razor spikes, flat wrap and razor wire.

Security spikes are fixed to the top rails.

Razor wire coils are fixed to the steel palisade with support arm brackets.

The design and details of brackets are different for various fencing projects, while y arm design is popular:

All holes for the attachment of Razor Wire Support Brackets are to be drilled into the Posts prior to Galvanizing, or on the Top Horizontal Rail Bracket Holes.

Palisade Fences Finishes

High Security Palisade Fence Systems

- Palisade Fencing for High Security Purpose

- Palisade Curved Fence Panels

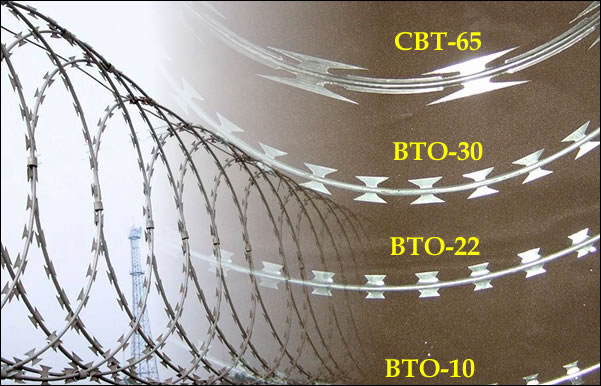

- Razor Barbed Wire

- Concertina Razor Barbed Wire

- Single Spiral Razor Wire

- Y Steel Palisade Fence with Concertina Razor Wire

- Chain Link Security Fencing

- Razor Spikes

- Weldmesh Panels

- Curved Welded Wire Mesh Fence Panels

- Fencing Gates

31 Xinjie, Development Area, Dezhou, China www.palisadefence.net sales@palisadefence.net

Copyright © 2020. Tripline Palisade Fence Co.