Palisade Fences, Galvanized, Powder Coated, Black Finishes

- Hot Dipped Galvanised Palisade Fencing

- Prefabricated Steel Palisade Fencing Painted

- Black Coated Steel Palisade Fencing

- Powder Coated Galv. Steel Palisade Fence

- Wrought Iron Palisade Fence

- GRP Palisade Fencing

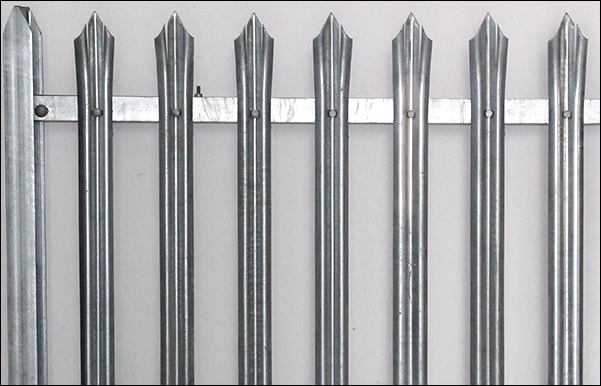

Steel Palisade Pale Types

Fencing Heads Shapes

- Palisade Fencing Tops General Intro

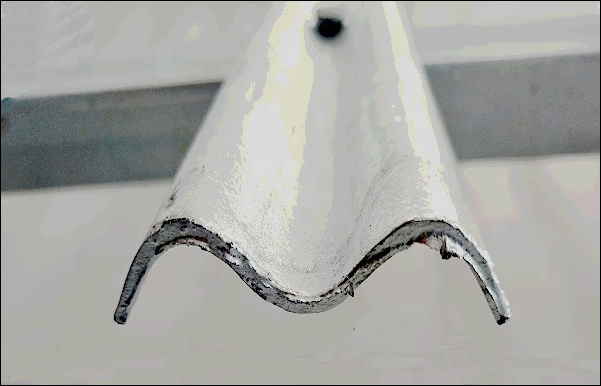

- Palisade Fence with Round and Notched Top

- Triple Spike Pointed Palisade Fence

- Single Pointed Palisade Fence

High Security Fence Systems

- Perimeter Safety Palisade Fence System

- Palisade Fence Hot Rolled Galvanized

- Substation Security Paliasade Fence

- Razor Wire Topped Palisade Fencing

- High Security Palisade Fencing

- Palisade Curved Fence Panels

- Razor Barbed Wire

- Concertina Razor Barbed Wire

- Single Spiral Razor Wire

- Y Steel Palisade Fence with Concertina Razor Wire

- Chain Link Security Fencing

- Fencing Razor Spikes

- Weldmesh Panels

- Curved Welded Wire Mesh Fence

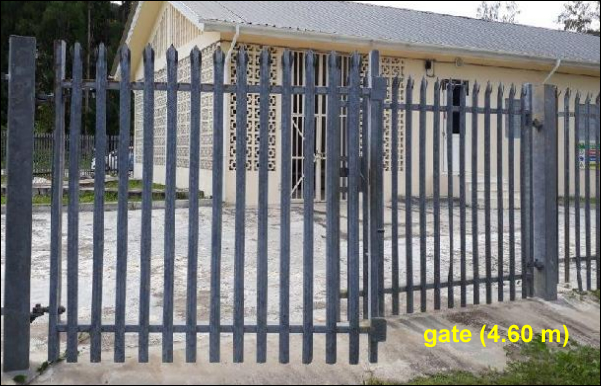

- Fencing Gates

PALISADE FENCE HOT ZINC (ZN) GALVANIZED FINISH

Hot Zinc Galvanised Steel Palisade provides secure border barrier for residences and various premises. Steel fencing galvanised can be coated with plastic or polyester to increase corrosion resisting property.

Material:Q235

Height: 1200mm/1500mm/1800mm/2100mm/2400mm/2700mm/3000mm/3600mm

Width: 2750mm per bay or as you requirement

Pale type: D type, W type

Head type: Pointed, Triple pointed, Rouned, Rouned and notched, Flat ,star

W pale thickness: 2mm ,

2.5mm,

3mm

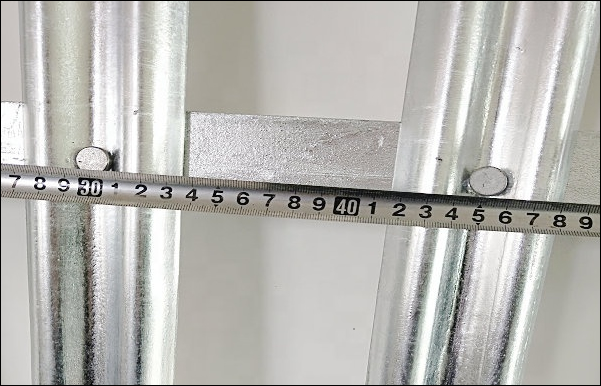

Angle rail: 50x50 RSA or 40x40 RSA

Rail thickness: 4mm/5mm/6mm

RSJ post: 100*55*3.5mm

Fish plate:150*30*7mm

Bolts & Nuts: M8×25mm-34pcs and M12×30mm-4pcs

Surface treatment: Hot dipped galvanized (500g/m2, 70um and others)

Fencing Types and Target Markets

Galvanised Palisade Fencing Kit with Fixings and Rails -2mm Pale Thickness

Profile: W-section

Top: Triple point 2mm profile

Height: 2.4m

Supplied with posts, all fixings and steel rails

Gates: Double leaf vehicle gates (6m opening, 3m each leaf)

Finish: Hot dipped galvanised.

Galvanised Steel Palisade Fence - 3mm Thick D Type, BS 1722 Standard

Palisade: 2.5m Length x 2.3m Height

Angle panels: 50mm x 50mm x 6mm

SHS: 100mm x 50mm x 6mm

Pales: 3mm thick x 68mm width x 2.2 metres height

Fabricated galvanized steel palisade fence D section pales 3mm thick

Fixing:

The pales shall be securely bolted onto three horizontal galvanized angle rails (50x50x6mm) positioned at the top, middle, and bottom.

The angle rails shall be fixed to two posts made out of 50x100x4mm galvanized rectangular hollowsections.

The end hollow section posts shall include an extended length of at least 1000 mm for embedding into concrete foundations.

Each panel shall have an overall size of 2500mmin length and 2200mm in height

All fixings shall utilize galvanized tamper-proof nuts and bolts.

Palisade Fencing Construction:

Perimeter Fence including Gates

Palisade fences designed and constructed to meet the requirements of BS fence type reference GP 24 in BS 1722 part 12 - table 1.

Palisade of 3.0mm thick profile, type corrugated "D" in accordance with BS 1722.

All fencing components, including punching or drilling of holes shall be hot dip galvanised in accordance with BS 729 and zinc coated in accordance with ISO 2081/ BS EN ISO 14713-1

Any small areas of hot dip galvanised coating damaged by welding, cutting, or excessively rough treatment during transit and installation shall be renovated by the use of powders made specifically for that purpose, or means in accordance with BS 5493, e.g. zinc rich paint.

2.4m High Palisade Fence Hot Dip Galvanized - S275 Material Grade

Materials: Hot dipped galvanized to BS EN 1461 Standard

Optional: Fence materials powder coated RAL colour

Welding: BS EN 1011-1, BSEN 1011-2

Fence mesh panels:Welded by electro fusion welding process

All bolts and nuts: Security type stainless steel

Material grade: S275 / equivalent

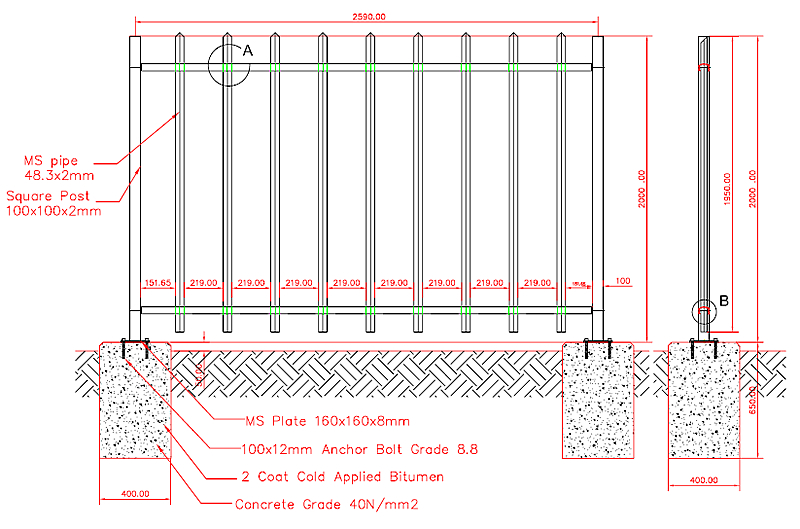

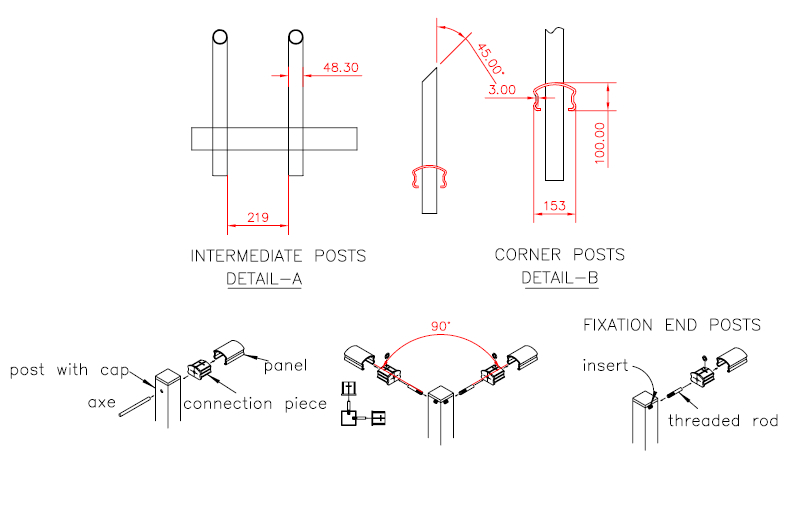

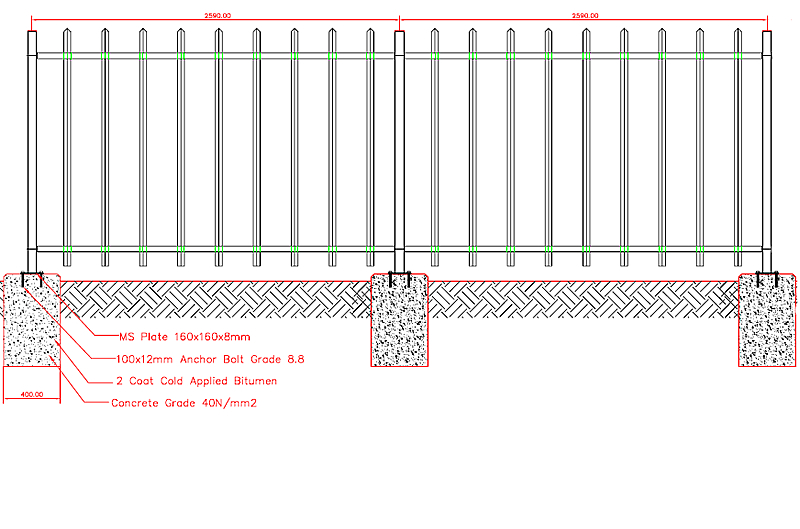

Galvanized Steel Palisade Fence Panels-Elevation

Steel Palisade Fence W Pale Triple Pointed Tops Galvanised to BS 1461

Manufacture, supply and install of steel palisade pales, rails, posts and gates, galvanised to BS 1461 standard

Pales: 2.0mm thick x 1950mm long 'W' pale, with 'triple pointed' tops, fixed on with M8 bolts and

permacone anti vandal nuts.

Rails: 50x50x6 RSA x 2 off, complete with loose fish plates and M12 cup square bolts and permacone

nuts.

Posts: Standard 100 x 55 RSJ, set at max 2750mm metre c/c. Dig-in into concrete footings.

Finish: Galvanised to BS 1461 only.

Full set of manually operated double leaf gates to the following specification:

Height: 2.0 Metres high (1950mm actual) x 4.1 Metres wide between posts. Inward Opening.

Gate Infill: Clad with 'W' palisade pales with triple point tops bolted to frames.

Frame: 80 x 40 RHS.

Posts: 100 x 100 SHS gate posts. Dig in into concrete footings.

Lock: Slide latch (padlock not included).

Finish: Galvanised to BS 1461 only.

Manually operated single leaf gate to the following specification:

Height: 2.0 Metres high (1950mm actual) x 1.6 Metres wide between posts. Inward Opening.

Gate Infill: Clad with 'W' palisade pales with triple point tops bolted to frames.

Frame: 80 x 40 RHS.

Posts: 100 x 100 SHS gate posts. Dig in into concrete footings.

Lock: Slide latch (padlock not included).

Finish: Galvanised to BS 1461 only.

Industrial Grade Palisade in galvanized finish, complete with all posts and fixings

2.50 M High Palisade Panels, HDG (Hot Dip Galv.) GI, delivered to Ireland

Panels of Horizontal Rails and Vertical Posts, Hot Dipped Galv.

Galvanized w pales 2mm

Hot Dipped Galvanized Steel Palisade for High Security Application

Anti-climbing W Pale Galvanized Palisade with Razor Wire

Panel size 2.1m high x 4m long

w pale : 80x19mm x 2.5mm thick x 2.05mm long with a single point 100mm long - w pale spaced at 160mm crs,

18 pales per panel

Rail : 50 x 80mm x 2.5mm thick x 4m long, 2 pce per panel

Reinforcing angle 50 x 50 x 2.5mm thick x 4m long,

1 pce per panel

Post : 100 x 150mm x 2.5mm thick x 4m long

Pale, rail, post & components all hot dipped galvanized at zinc quantity 600g/m2

Fasteners : stainless steel bolts with tamper resistant

shear off security nuts

Razor wire: Hot dipped galvanized razor barbed tapes

Gates: Hot dipped galvanized finish as fence

With gate posts,chains, locks, drop bolts and accessories

3 x sets vehicle gates double leaf x 4m wide

4 x sets vehicle / crash gates double leaf x 6m wide

3 x sets pedestrian gates single leaf 2.1m h x 1m wide

Palisade Hot Dip Galvanized and PVC coated

Building project of cell sites for wireless telecoms industry in Nigeria.

Hot dipped galvanized palisade fencing material for cell sites:

Supply and installation of 2m Hot dip galvanized steel palissade with barbed wires (0,5m additionnal height)

3m wide entrance gate for GF site with hot dip galvanized steel palissade with locking arrangement

Fence as per drawing below.

Full system should be Hot Dip Galvanized and PVC coated.

Steel Palisade Fence supplied to Thailand construction contractors

Specification

Pales: 2,500 mm with triple point head settings

Horizontal rails to be Angle 50 x 50 x 6mm

Stanchions to be constructed from 100 x 50 x 5mm or equipvalent

Rails secured with snap off heads

Hot dipped galvanised

High Security Palisade Fencing System in Kit Form, to Cork, Ireland

2.40 metre palisade fencing Galvanised Hot dipped in kit form.

Palisade 2mm w triple pointed in green coated gi finish.

2.4 m high with posts and fixings

Steel Palisade Perimeter Fencing for USA, Building Material

Height: 1.8, 2.0 and 2.4m

D and W section triple pointed top

For Wall Perimeter Systems

2350mm high Fencing Components, Galvanised, Delivery to Ireland

W pale thickness: 2mm, 2.5mm, 3mm

Supply with additional posts, additional angles

Target country: Ireland

Typical Galvanised Palisade Fencing System Project - Sewerage Station Fencing - Detailed with Diagrams

Seychelles Project - Palisade Fencing for Sewerage Pump Stations

Main system:

Palisade fencing & entrance gate:

Palisade fencing of 2.4 meters height "W" Section Triple Pointed palisade Security fencing

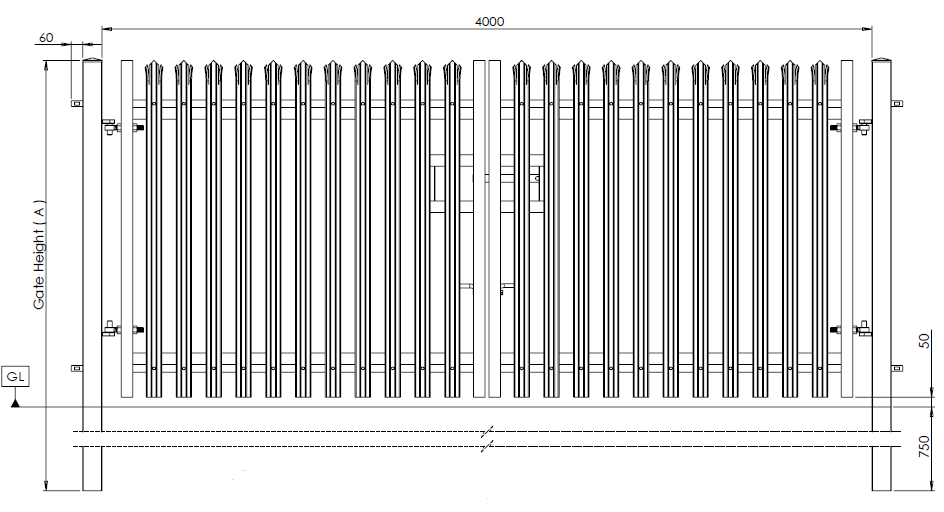

Palisade Entrance main gate (Double Leaf Design with Inbuilt Man Access Door) with the dimensions of 4.0 meter wide and 2.4 m height.

2.4m High Palisade Fencing End Post set consists of 4 M12 bolts, two specialist end fishplates

Single and Double Leaf Palisade Gates Featuring "W" Profile Pales

| Single Leaf Gate Height (A) |

Floor Fixing Method |

Frame | Posts | Embeded Lenght |

Base PLate Size | Pale Type | Finish | Drop Bar |

| 1800mm | Concrete in Post |

80 x 80 x 5 | 80 x 80 x 5 | 750mm | NA | "W" Profile Pales As Standard |

All Gates have a Galvanised finish as Standard BS1772 |

Included As Standard |

| 2000mm | 80 x 80 x 5 | 80 x 80 x 5 | ||||||

| 2400mm | 80 x 80 x 5 | 80 x 80 x 5 | ||||||

| 3000mm | 100 x 100 x 4 | 100 x 100 x 4 |

Gate Specifications

1) all gates come with 'w' profile pales which are 3mm for security purposes

2) as a climbing deterrent all pales are triple pointed

3) snap off nuts used to ensure gates are tamper proof

4) gates are supplied with a high quality finish. as standard they are galvanised to bs1722.

5) these gates designed to accompany palisade fencing and provide the ultimate security.

6) palisade gates come complete with a slide latch with two padlock holes & drop bars

7) as standard all gates are left hung when viewed front face

8) all gates open both inwards & outwards

9) All gates come with a full pale over the latch, holes are provided on the latch frame.

10) The latch handle is reversible.

Double Leaf Gate Diagrams

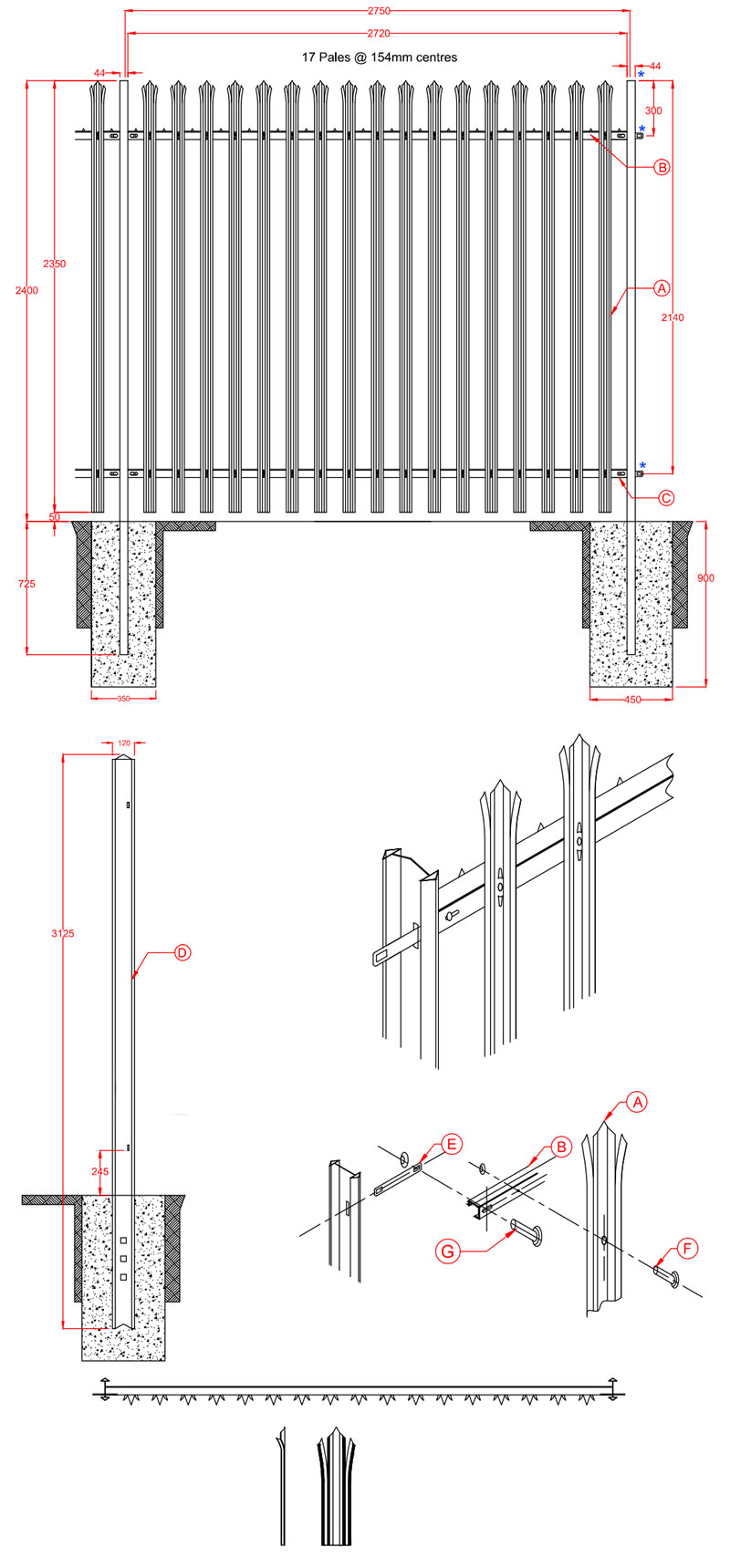

Palisde Fencing Panels SPECIFICATIONS:

Materials: Steel Zinc Plated Galvanised to BS EN ISO 1461:2009

Pales : 17 pales per palisade panel with 2350 mm Height X 65 mm width and 3.0mm thickness per Bay of 2.75 Meter

Crossbars: 2 crossbars per palisade panel top and bottom. Other materials of angle iron and holes to receive pale bolts. 2720 x 45mm

Posts: 1 post per palisade Bay of 2.75 Meter; 3125x120x44 mm with cap (total 260 posts).

Fish Plates : 2 Fish Plate per Bay 130x30 mm

Nuts and Bolts: 34 per palisade panel; M8 x 25 Snap off Bolt and Cone nut.

Rail Fixing Bolts and Nuts : 4 Per Bay M12x30 Snap off Bolt and Cone nut

Components with dimensions:

W section pale: 2350 x 65mm

Top rail: 2720 x 45 mm

Bottom rail: 2720 x 45 mm

Post: 3125 x 120 x 44 mm

Fish plates: 130 x 30 mm

Pale fixing M8 x 25mm bolt + snap off nut

Rail fixing M12 x 30mm bolt + snap off nut

Quality Standards of Galvanized Fencing Materials

We manufacture and distribute steel fencing with Hot dip galvanized coating as per international standards: IS 2629/IS 4759/ASTM A123 / IS 4736 / ASTM A153 / BS EN 1461 / SABS 763.

Options:

American standard:

ASTM A153 for Hardware hot dip zinc coating set by American Galvanizers Association

British, European and International standard:

BS EN ISO 1461:2009, The British, European and International standard for hot-dip galvanizing

The standard specifies a minimum coating thickness of hot dip galvanized coatings on fabricated iron and steel articles, to be applied to steel in relation to the steels section thickness

South African Standard:

SABS 763 ( South African Bureau of Standards for Civil Engineering Construction)

Hot Dip (Galvanized) Zinc Coating shall complies with the requirements of SABS 763 for coating layer.

STEEL PALISADE FENCE HOT DIPPED GALVANIZED SABS 763 STANDARD

All material galvanized to SABS 763.

Posts. {Refer to figure 2) 76 mm x 76 mm x 3 mm, 3000 mm square tubing set into 15 Mpa concrete foundations, 400 x 400 x 600 mm each 3000mm tubing shall be fitted with a 40 x 6 x 200 mm base plate which allows for drainage.

All posts shall have pyramid caps fitted on top with silicon. Corner posts must be fitted with 30 x 6 x 20 mm earth tabs, 815 mm from the bottom. The earth tabs must face the inside and must have a 13 mm hole drilled in the centre. 75 x 50 x 5 mm L-brackets 62 mm long must be welded to the posts with a 13mm hole drilled through the middle for M 12 x 40 mm bolts with snap nuts to secure the panels to the posts.

Palisade Panels. (Refer to figure 3)

Three panel sizes available.

825 x 2350 mm

1200 x 2350 mm

2100 x 2350 mm

The palisade

panels can be bolted together with galvanized M10 x 40 Cap Square bolts and snap nuts ( inland) and M8 x40 stainless Cap Square bolts and snap nuts (coastal).

Top Rails for Palisade Panels. (Refer to Figure 3)

76mm x 50mm x 6mm angle iron with the 76 mm Leg facing down.

At the end of the rail a 13mm hole must be drilled through the centre for M12 mounting bolts.

Razor spikes must be fitted to top rails by means of 6 mm pre-drilled holes (before galvanizing) and secured with 4.8 mm full stainless steel pop rivets.

Bottom Rails for Palisade Fencing Panels. Identical to top rails, without the spikes.

Pales.

3mm thick pales from steel - 65mm wide and 2350 mm long, the top must be spear or trident.

The top of the pales inline with top of the post caps.

The distance between the concrete apron and the bottom of the pale is 50 mm.

Razor Fencing Spikes for Palisade Panels

Top rail fitted with two 70 x 6 x 120 x 80 mm L - Brackets between the two gate posts.

Razor spikes to be fitted to top rails by means of 5 mm pre-drilled holes (before galvanizing) and secured with 4.8 mm full stainless steel pop rivets.

Razor spikes materials are hot dipped galvanized, stainless steel materials are used for ocean areas.

Palisade Fence Installation and Erecting Tips

The fence will be erected using M12 galvanised blind head bolts and nuts fitted with neoprene washers inland, and M 12 stainless steel bolts and nuts fitted with cotton reinforced washers at coastal regions. No welding is to take place after galvanizing. At sites where a steel palisade fence is to be used the fence shall be erected using the following materials: figure 1

The fence post connections to the horizontal rail will be erected using M12 hot dip galvanised cup square bolts and nuts and washer (inland), and M12 stainless steel bolts, nuts and washer in coastal regions. The threads are to be damaged after installation. The washer is to be inserted on the nut side of the connection, and the nut side shall face toward the inside of the site. No welding is to take place after galvanising. All mild steel bolts shall be treated with mono seal on the nut end after being tightened.

Steel Palisade Pedestrian Gate -Square Tubing

1124 mm x 1878 mm high gate frame and pales of 2350 mm height

Fabricated from 38 mm x 38 mm x 3mm square tubing.

The gates have the following: (Refer to figure 4, 5 and 6)

Stainless steel sliding bolt 16 mm diameter, fitted to the gate, with a 5mm stainless steel tab on the sliding bolt and a 5 mm tab on the gate frame with 20 mm holes, to accommodate a 12 mm padlock. Stainless steel is grade 304.

Steel guard plate at 5mm is welded to the gate frame at the position of the sliding bolt to prevent the gate from opening to the inside. The steel guard plate must hide the sliding bolt from the front and act as a gate handle.

Pales: 3mm thick pales from steel 65mm x 1840 mm in size, the top spear or trident. The pales must be bolted to the gate frame with M8 x 80 mm Cap Square stainless steel bolts and snap nuts with a 1.6 mm thick stainless steel washer on the nut side. The gate pales extend to the same height as the fence pales.

The gate opening is 1200 mm, allowing for a 30 mm gap between the gate and posts on the lock side, and a 46 mm gap on the hinge side.

The distance between the concrete apron and the bottom of the gate must be 50 mm.

Top rails and razor spikes for Palisade Gates

76 x 38 x 3 x 1200 mm long gate top rail fitted with two 70 x 6 x 120 x 80 mm L - Brackets between the two gate posts.

Razor spikes must be fitted to top rails by means of 5 mm pre-drilled holes (before galvanizing) and secured with 4.8 mm full stainless steel pop rivets.

Two bullet hinges with a 20 mm loose fitting, for galvanizing purposes must be welded to the gate and the gate housing frame 200 mm from the top and the bottom of the gate.

8mm round bar spacers used when welding the bullet hinges to the gate and gate posts. The gate will open outwards. When standing outside and facing the gate, the hinges will be on the right and the locking mechanism will be on the left. A grease nipple is fitted after galvanizing to the female part of the hinges for greasing the hinges. Stainless steel nipples are used at coastal regions.

All steel used in the construction of the gate shall be hot dip galvanized SABS 763.

Steel Palisade Motor Gate

Two 1439 mm wide x 1878 mm high gate frames shall be fabricated from 38 mm x 38 mm x 3mm square tubing. The right hand side of the left gate and the left hand side of the right gate (the two vertical square tubing must extend past the bottom horizontal member of the frame) must be in line with the bottom of the pales.

The motor gates shall have the following: (Refer to figure 5, 6, 7)

3mm thick pales from steel merchants 65mm wide and 2350 mm long, the top must be spear or trident. The pales must be bolted to the gate frame with M8 x 80 mm Cap Square stainless steel bolts and snap nuts with a 1.6 mm thick stainless steel washer on the nut side. The gate pales shall extend to the same height as the fence pales.

360 x 16 mm diameter stainless steel sliding bolt is fitted through the frame on the left hand side of the right hand leaf, with a 5 mm stainless steel lab on the sliding bolt and a 3 mm tab on the gate with 20 mm holes to accommodate a 12 mm padlock. When in the locked position the sliding bolt shall protrude through the frame of the second gate through a 20 mm hole by no less than 10 mm. A second 1250 x 16 mm diameter stainless steel sliding bolt will be set in a vertical position on the right hand side of the left gate leaf. This bolt must be set into a 25 x 50 x 3 mm housing in the concrete and the top of the bolt must have a stainless steel 5 mm tab with a 20 mm hole to accommodate a 12 mm padlock in the same position as the horizontal sliding bolt tab when in the locked position. The sliding mechanism must have three welded 5 mm tabs with 20 mm holes for the bolt on the inside of the gate frame. The sliding bolt must have a 8 mm tab supporting the bolt in the open position welded to the gate frame. Stainless steel must be grade 304.

5 mm thick steel guard plate is welded to the gate frame at the position of the sliding bolt to prevent the gate from opening to the inside. The steel guard plate must hide the sliding bolt from the front and act as a gate handle.

3000 mm opening with 76 x 76 x 3 mm square tubing set into 15MPA concrete foundations, 450 x 450 x 475mm on either side of the opening shall be provided for hanging the gates. A 76x 38 x 3 mm horizontal top rail shall be bolted to the top of the vertical rails by means of a L bracket 70x6x120x80 mm that is welded to the vertical rail (facing inwards) and two M 12 x 60 mm galvanized blind bolts set 80 mm apart in each joint. Neoprene washers are to be used on the bolts to waterproof the holes in the rail. The open ends must be capped. Razor spikes must be fitted to top rails by means of 6 mm pre-drilled holes (before galvanizing) and secured with 4.8 mm full stainless steel pop rivets.

The distance between the concrete apron and the bottom of the gate must be 50mm.

Two bullet hinges with a 20 mm loose fitting pin, for galvanizing purposes must be welded to the gate and the gate housing frame 200 mm from the top and the bottom of the gate. 8mm round bar spacers must be used when welding the bullet hinges to the gate and gate posts. The gate will open outwards. A grease nipple must be fitted after galvanizing to the female part of the hinges for greasing the hinges. (Stainless steel nipples must be used at coastal regions.)

All steel used in the construction of the motor gate shall be hot dip galvanized SABS 763.

Palisade Fences Finishes

High Security Palisade Fence Systems

- Palisade Fencing for High Security Purpose

- Palisade Curved Fence Panels

- Razor Barbed Wire

- Concertina Razor Barbed Wire

- Single Spiral Razor Wire

- Y Steel Palisade Fence with Concertina Razor Wire

- Chain Link Security Fencing

- Razor Spikes

- Weldmesh Panels

- Curved Welded Wire Mesh Fence Panels

- Fencing Gates

31 Xinjie, Development Area, Dezhou, China www.palisadefence.net sales@palisadefence.net

Copyright © 2020. Tripline Palisade Fence Co.